Aspalt Patching

Hook-Lift

Grab-and-Go Patching Capability

With a Thermo-Lay hook-lift unit, you can maximize fleet versatility and avoid the chassis procurement delays.

A built-in hydraulic power system makes this machine completely self-contained. Just mount the unit on your existing hook-lift chassis whenever you need to make road repairs. Thermo-Lay offers compatibility with all hook-lift brands.

Available sizes: 2 yd³ • 4¼ yd³ • 6¼ yd³

Safer

- Multiple e-stops

- Safety lockouts

- No-climb design

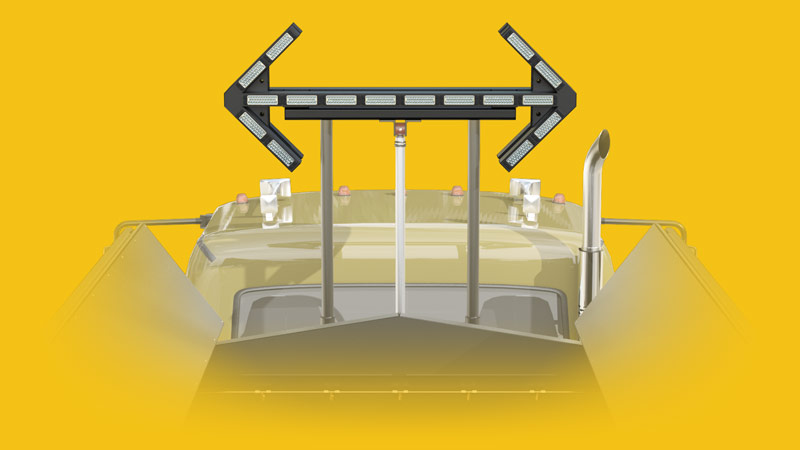

- Telescoping arrow board

- Safety flashers

Simpler

- Touchscreen interface

- Canbus control technology

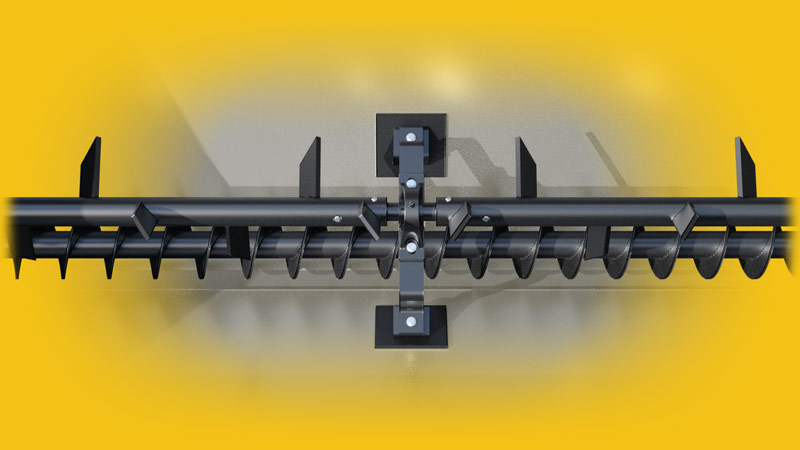

- No-clog dispense (auger, anti-bridge bar, release agent applicator)

- Telescoping arrow board

- Radiant oil heat for constant, even temps

Tougher

- Heavy-gauge welded steel

- Low-wear HD steel auger

- Powerful, actively cooled hydraulics

- Protective industrial coating

Innovative

Every Thermo-Lay machine has a state-of-the-art CAN bus control system that gives fingertip access to all functions. The technology reduces wiring, boosts reliability, and has onboard diagnostics to streamline remote troubleshooting.

Best of all, the controls prioritize safety, with interlocks and e-stops to protect your crew.

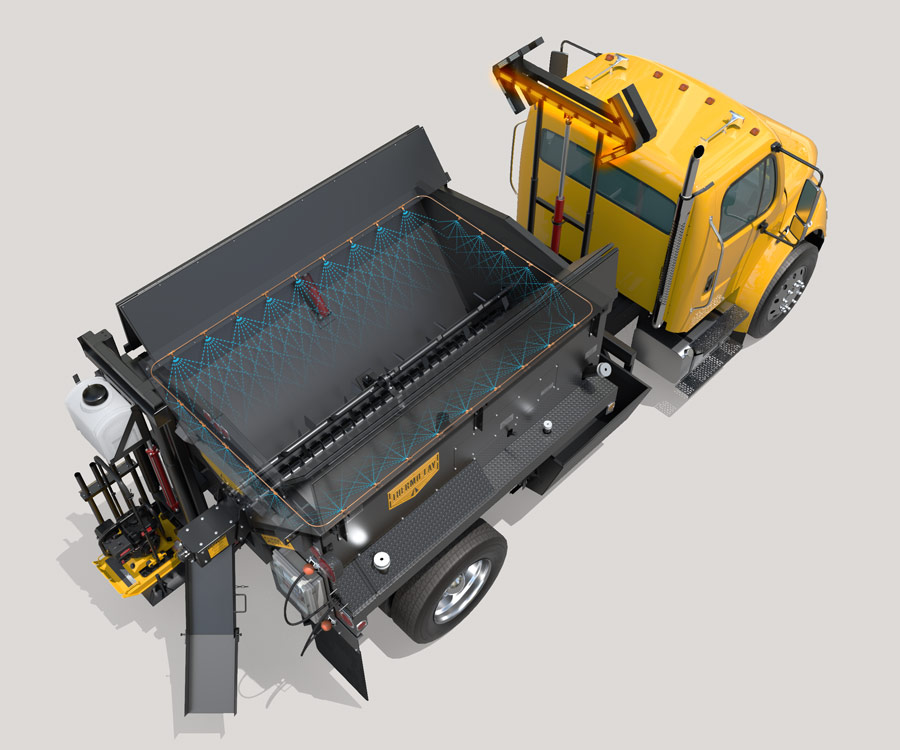

Our propane-fired radiant oil heating system envelops the hopper, maintaining asphalt and tack tank temperature with superior consistency and uniformity.

Thermo-Lay’s automated release agent spray system coats the hopper walls to prevent asphalt from sticking. It helps ensure smooth material flow, and it eliminates a reason for your personnel to climb the truck or enter the hopper.

Walkaround

Sure, you love videos. But there’s no substitute for hands-on experience. Ready to test-drive a Thermo-Lay? Schedule an onsite demonstration today:

Preferred by Pros

Gallery

Your Crew DeserveS One

With a Thermo-Lay, your crew is equipped to fix failing pavement, reduce work order backlog, and stay safe out in the field.